+86 134 0021 8776

+86 134 0021 8776

News

Nov. 30, 2023

Summarize

FPC, also known as flexible printed circuits, is favored for its excellent properties such as light weight, thin thickness, and free bending and folding. With the rapid development of the electronics industry, circuit board design is developing more and more in the direction of high precision and high density. The traditional manual inspection method can not meet the needs of production, and the automatic inspection of FPC defects has become an inevitable trend of industrial development.

FPC synthetic material

1 Insulating film, the insulating film forms the base layer of the circuit, and the adhesive will bond the copper foil to the insulating layer. In a multi-layer design, it is bonded to the inner layer. They are also used as protective caps to protect the circuit from dust and moisture, and to reduce pressure when bending. Copper foil forms a conductive layer.

2 conductor, copper foil suitable for use in flexible circuits. It can be electrodeposited (ED) or electroplated. The electrodeposited copper foil has a shiny surface on one side, while the processed surface on the other side is dull. It is a flexible material that can be made in many thicknesses and widths. The matte surface of ED copper foil is often specially treated to improve its bonding ability. In addition to flexibility, forged copper foil also has the characteristics of rigidity and smoothness.

Adhesives, adhesives in addition to the insulation film bonded to the conductive material, can also be used as a covering layer, as a protective coating, as a covering coating. The main difference between the two is the application method used. Not all laminate structures contain adhesives, and laminates without adhesives form thinner circuits and greater flexibility. Better thermal conductivity compared to adhesion-based laminate structures. The thermal conductivity is improved due to the thin structure of the binderless flexible circuit and the elimination of the thermal resistance of the adhesive.

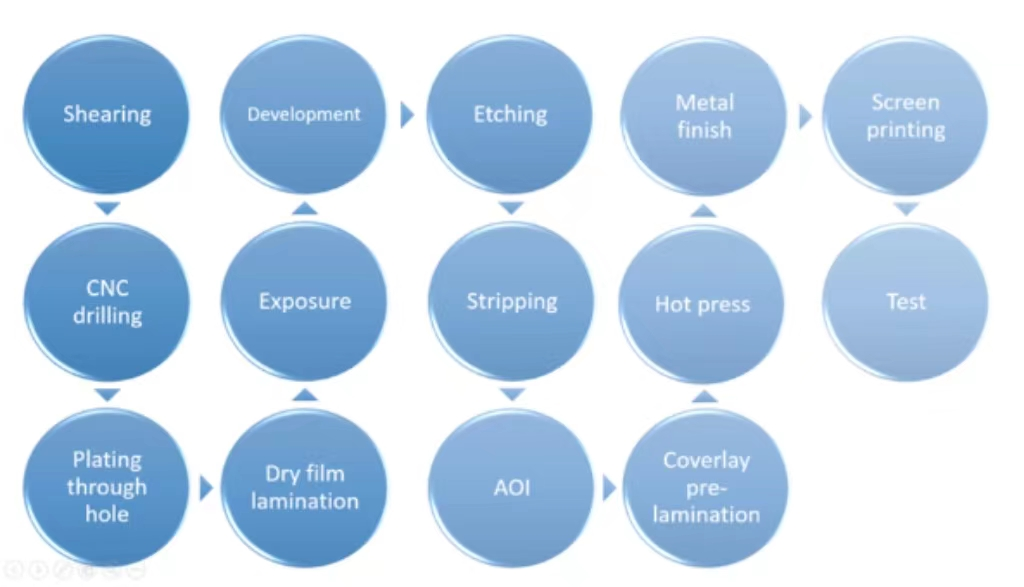

FPC production process

There are many types of FPC, single-sided FPC, double-sided and multi-layer.

1 Double-sided or multi-layer board circuit board process flow, Cutting → drilling →PTH→ Electroplating → Pretreatment → dry coating → alignment → exposure → Development → Graphic plating → Stripping → pretreatment → Dry coating → alignment exposure → Development → Etching → stripping → Surface treatment → pasting cover film → Pressing → curing → Dipping nickel plating → printing text → cutting → electrical test → punching → Final inspection → Packaging → Shipping

2 Single-panel circuit board process flow, cutting → drilling → paste dry film → alignment → exposure → development → etching → stripping → surface treatment → film covering → pressing → curing → surface treatment → nickel gold leaching → printing → cutting → electrical measurement → punching and cutting → final inspection → packaging → shipping

Advantages and disadvantages of FPC

1 Advantages of flexible printed circuits

Flexible printed circuit board is a printed circuit made of flexible insulated substrate, which has many advantages that rigid printed circuit boards do not have:

1. It can be freely bent, wound, folded, arbitrarily arranged according to the spatial layout requirements, and can be moved and expanded in three-dimensional space, so as to realize the integration of component assembly and wire connection.

2. The use of FPC can greatly reduce the volume and weight of electronic products, which is suitable for the development of electronic products in the direction of high-density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, notebook computers, computer peripherals, PDAs, digital cameras and other fields or products.

3.FPC also has the advantages of good heat dissipation and weldability, easy assembly and low overall cost. The combination of soft and hard design also makes up for the slight deficiency of the flexible substrate in the load-carrying capacity of the components to a certain extent.

2 Disadvantages of flexible printed circuits

1. High one-time initial cost: Since flexible PCBS are designed and manufactured for special applications, the initial circuit design, wiring and photography master require higher costs. Unless there is a special need to apply flexible PCBS, it is usually best not to use them in a small number of applications.

2. The replacement and maintenance of FPC is difficult: Once the flexible PCB is made, it must be changed from the bottom drawing or programmed drawing light program, so it is not easy to change. The surface is covered with a protective film, which must be removed before repair and restored after repair, a relatively difficult task.

3. Limited size: Flexible printed boards are usually manufactured by batch methods when they are not yet popular. Therefore, due to the size of the production equipment, they cannot be made very long and wide.

4.Easy to damage: Improper operation of installation and connection personnel can easily cause circuit damage, and its welding and rework require trained personnel to operate.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote