+86 134 0021 8776

+86 134 0021 8776

Oct. 14, 2024

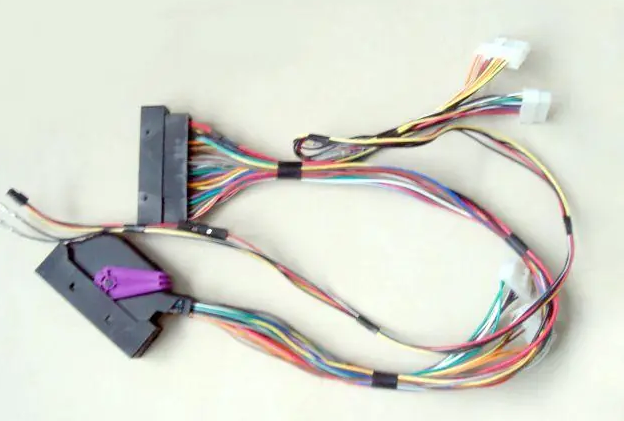

Automobile wiring harness is the main body of automobile circuit network, and there is no automobile circuit without wiring harness. Wire harness refers to a component that is connected to a circuit after the contact terminal (connector) made of copper is crimped with a wire and cable, and then plasticized to an insulator or an external metal shell. Wire harness industry chain includes wire and cable, connectors, processing equipment, wire harness manufacturing and downstream application industry, wire harness application is very wide, can be used in automobiles, household appliances, computers and communication equipment, various electronic instruments and meters, the body wire harness connected to the entire body, the general shape is H-shaped.

With the continuous improvement of people's requirements for comfort, economy and safety, the types of electronic products on the car are also increasing, and the failure rate of the car's wiring harness is becoming more and more complex. This requires to improve the reliability of wiring harness and durability, such as performance, many people are interested for the process and production of automotive wiring harness, automotive wiring harness technology and production here this knowledge to make a simple narrative.

After the two-dimensional product drawing of the automobile wiring harness comes out, the production process of the wiring harness should be arranged, and the process is inseparable from the two that serve the production, so the production and process of the automobile wiring harness should be combined to analyze together.

Wiring harness production line technology is the first station. The accuracy of the opening process is directly related to the entire production schedule, once there is an error, especially the opening size is short, it will lead to rework of all stations, time-consuming and laborious affecting the production efficiency. So in the preparation of line technology is must according to the requirement of the drawing reasonable conductor line size, size of strip head.

Line after the second location is crimping process, type of terminal crimping parameters according to your drawings, crimping operation instructions, for the needs of the special requirement on the process documents indicating and train operators. For example: some wires need to pass through the sheath before crimping, it needs to pre-assemble the wire and then return from the pre-assembly station to crimping; And punctured type pressure or move to a dedicated tools, this method has good electrical contact pressure to performance.

Then is the pre-assembly process, first of all to prepare the pre-assembly process operating instructions, in order to improve the assembly efficiency, complex wiring harness to set the pre-assembly station, the pre-assembly process is reasonable or not directly affects the efficiency of the total assembly also reflects the technical level of a process personnel. If the pre-assembled part of the assembly is less or the assembly wire path is inappropriate, the workload of the total assembly personnel will be increased and the speed of the assembly line will be slowed down, so the process personnel will often stay on the site and constantly summarize

The final step is, the assembly process. Be able to design tooling equipment, material box specifications and dimensions according to the assembly table designed by product development department, and attach the numbers of all assembly jackets and accessories to the material box to improve assembly efficiency. Prepare the assembly content and requirements of each station, balance the entire assembly station to prevent a bit of excessive workload and pull down the speed of the entire assembly line. To achieve station balance, the process personnel must be familiar with each operation and calculate the working time on site, and adjust the assembly process at any time.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote