+86 134 0021 8776

+86 134 0021 8776

Jan. 19, 2024

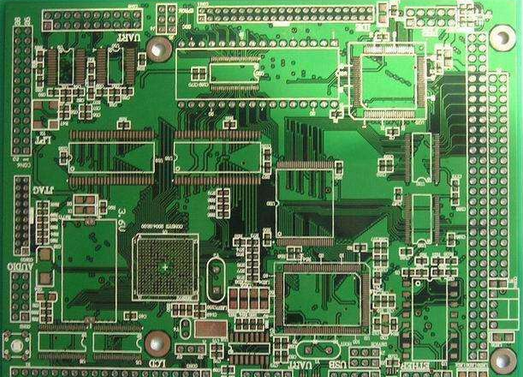

With the continuous improvement of human living environment requirements, the environmental problems involved in the PCB production process are particularly prominent. The topic of lead and bromine is the hottest, Lead free and non halogenated will affect the development of PCB in many ways.

Although for now, The surface treatment process of PCB has not changed much, But it should be noticed. Long periods of slow change will lead to dramatic changes. In the case of increasingly high environmental protection voices, The surface treatment process of PCB will certainly change greatly in the future.

The basic purpose of surface treatment is to ensure good solderability or electrical properties. Because copper in nature tends to exist in the air in the form of oxides, unlikely to remain as raw copper for a long time, So copper treatment is therefore necessary.

here are many PCB surface treatment processes now, following will be introduced one by one:

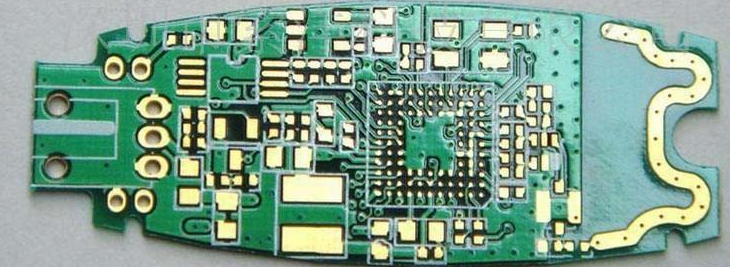

* HASL

Hot air leveling, also known as hot air solder leveling (commonly known as tin spray), It is the process of coating molten tin (lead) solder on the surface of PCB and blowing (blowing) flat with heated compressed air, and make it a layer that is resistant to copper oxidation, and supply coating with good solderability. During the hot air, solder and copper combine to form copper tin intermetallic compounds.

* OSP

OSP also called Organic Solderability Preservatives, Simply speaking, OSP is on the surface of cleaning bare copper, chemically grown a layer of organic film. The film has oxidation resistance, heat shock resistance and moisture resistance. Used to protect the surface of copper from corrosion in the normal environment.

* Full plate nickel plated gold

The gold plated nickel plate is plated with a layer of nickel on the surface conductor of PCB and then plated with a layer of gold. Nickel plating is mainly to prevent the diffusion of gold and copper. Soft gold is mainly used in chip packaging gold wire. Hard gold is mainly used in non welding electrical interconnections.

* Immersion Gold

The gold is a thick, electrically charged nickel alloy on the copper surface. this can protect PCB for a long time. In addition, it has the environmental tolerance that other surface treatment processes do not have. Immersion gold can also prevent the dissolution of copper.

* Immersion Tin

Since all solders are based on tin, the tin layer matches any type of solder. Tin deposition process can form a flat copper tin intermetallic compound.

* Immersion silver

The silver deposition process is between organic coating and electroless nickel plating / immersion, the process is simple and fast. Silver can still maintain good solderability even when exposed to heat, humidity, and contamination.

*Electroplated hard gold

In order to improve the wear resistance of products, increase the number of plugging and electroplating hard gold.

Previous: FPC circuit board for drones

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote