+86 134 0021 8776

+86 134 0021 8776

Nov. 07, 2024

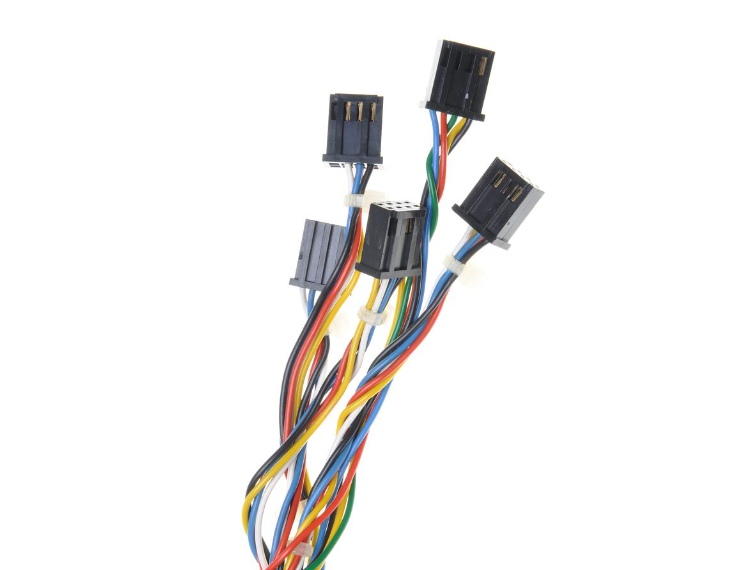

What is an electronic harness?

In the most common terms, the electronic beam is the wire that electronically controls the input and output.

Electronic wiring harness processing process

1. Cutting wire: Check whether the standard type of wire is correct; The scale is not in line with the requirements

2. Peeling: Check whether the peeling mouth is flat, can not peel the damaged core wire, marshalling silk, etc., peeling scale is correct.

3. Grouping disposal: whether the pruning scale is correct, whether the pruning is flush, and the core wire cannot be hurt when trimming the grouping

4. Peeling the endothelium: check whether the peeling mouth is level; Peeling scale is correct; There is no damage to the core wire, broken copper wire; Insulators must not fall off during half-stripping.

5. Set of shortened tube: check whether the size and type of shortened tube are correct.

6. Prepare the solder: check the temperature of the tin furnace is correct; Is there a copper wire bifurcation, big head, uneven copper wire and burnt insulation after preparing the solder?

7. Soldering: Check whether the temperature of the electric iron is correct; Can not burn insulation, tin point should be lubricated, wuxi tip, not fake welding, virtual welding.

8. Terminal press: Admit that the standard of terminals and wires is correct; Whether the terminal is pressed with a horn, skew, and whether the insulation skin and core wire are exposed

Too long or too short.

9.Terminal piercing: Check whether the connector and terminal type are correct; Whether the terminal damage, deformation and other appearances; Whether the terminal is misinserted, misinserted, or inserted.

10.Wire crimping: check whether the type of connector is correct; Whether the direction of the wiring is correct; Whether the core wire is damaged, exposed copper, or scalded;

11. Blow the shortened tube: the shortened tube is not outstanding and can not burn the insulation.

12. Assembling the shell: the shell is not installed wrong, there is no scratch, rough edge and other bad, there is no missing parts, there is no screw, oxidation, discoloration, loosening and so on

Poor, no poor conformity after assembly; If the shell is oriented, it must be assembled according to demand.

13. Labeling: Check whether the content of the label is correct, clear, and without hyphenation; Whether the scale of the label is correct; Labels are dirty and broken

Damage; Whether the label is posted in the correct orientation.

14. Tie the tie: check the standard, color, orientation of the tie is correct; No cracking, loosening appearance.

15. Injection molding: Check whether there is dirt on the mold, whether there is a lack of material, bubbles, poor bonding, poor hardening and so on.

16 Plug molding: Check whether the plug molding is damaged, uneven, lack of material, raw edge, debris, flow and other bad, admit that the metal terminal is not deformed,

Damage, exposure of copper, etc.

17. Electrical view: View according to the requirements of the corresponding product's view guide ticket.

18. Appearance view: Pay attention to all items that can be seen to view.

Previous: The development prospect of wire harness

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote