+86 134 0021 8776

+86 134 0021 8776

News

Aug. 15, 2023

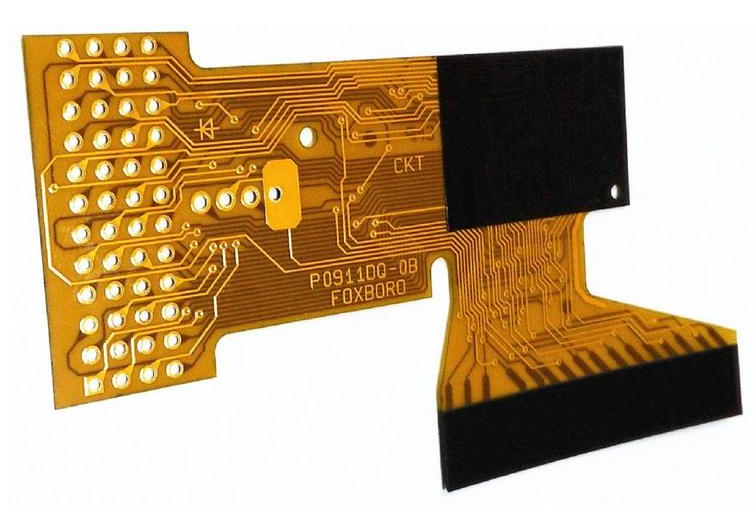

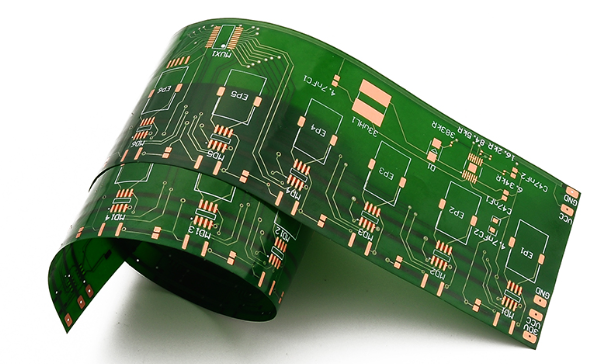

Flexible Printed Circuit board (FPC) is a highly reliable, excellent flexible printed circuit board made of polyimide or polyester film as a substrate. It has the characteristics of high wiring density, light weight, thin thickness and good bending.

1.Product introduction

Flexible circuit board (FPC), also known as flexible circuit board, flexible circuit board, its light weight, thin thickness, free bending and folding and other excellent characteristics are favored. However, the domestic quality inspection of FPC mainly relies on manual visual inspection, which is high cost and low efficiency. With the rapid development of the electronics industry, circuit board design is becoming more and more high-precision and high-density, and the traditional manual detection method can no longer meet the production needs, and the automatic detection of FPC defects has become an inevitable trend of industrial development.

Flexible circuit (FPC) is a technology developed by the United States for the development of space rocket technology in the 1970s. It is a printed circuit with high reliability and excellent flexibility made of polyester film or polyimide as the substrate. By embedding the circuit design on a flexible thin plastic sheet, a large number of precision components are embedded in a narrow and limited space. Thus forming a flexible circuit that is flexible. This circuit can be bent and folded at will, light weight, small size, good heat dissipation, easy installation, breaking through the traditional interconnection technology.

2.Basic structure

Copper Film (Copper Film)

Copper foil: basically divided into electrolytic copper and calendered copper two kinds. Common thicknesses are 1oz 1/2oz and 1/3 oz

Substrate film: Common thickness of 1mil and 1/2mil two kinds.

Glue (adhesive) : thickness depends on customer requirements.

Cover Film

Cover film: for surface insulation. Common thicknesses are 1mil and 1/2 Mil.

Glue (adhesive) : thickness depends on customer requirements.

Release paper: Avoid adhesion of foreign bodies before pressing; Easy to work with.

PI Stiffener Film

Reinforcing plate: reinforcing the mechanical strength of FPC to facilitate surface installation. Common thicknesses range from 3mil to 9mil.

Glue (adhesive) : thickness depends on customer requirements.

Release paper: Avoid adhesion of the adhesive before pressing.

EMI: Electromagnetic shielding film to protect the circuit board from external interference (strong electromagnetic area or vulnerable to interference area).

3.Merits and demerits

Advantages of Flexible circuit Board (FPC) :

Flexible printed circuit boards are printed circuits made of flexible insulating substrates, which have many advantages that hard printed circuit boards do not have:

(1)It can be freely bent, wound and folded, arbitrarily arranged according to the spatial layout requirements, and arbitrarily moved and expanded in three-dimensional space, so as to achieve the integration of component assembly and wire connection;

(2)The use of FPC can greatly reduce the size and weight of electronic products, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products.

(3)FPC also has the advantages of good heat dissipation and weldability, easy installation and low comprehensive cost, and the combination of soft and hard design also makes up for the slight deficiency of the flexible substrate in the bearing capacity of the component to a certain extent.

Disadvantages of flexible circuit board (FPC) :

(1) High one-time initial cost: Because the flexible PCB is designed and manufactured for special applications, the cost of the initial circuit design, wiring and photographic plate is higher. Unless there is a special need to apply soft PCB, usually a small amount of application, it is best not to use;

(2) The change and repair of soft PCB is more difficult: once the flexible PCB is made, the change must start from the base drawing or the light drawing program prepared, so it is not easy to change. Its surface is covered with a protective film, which should be removed before repair and restored after repair, which is a relatively difficult work;

(3) The size is limited: soft PCB is usually manufactured by intermittent process in the case of not common, so it is limited by the size of the production equipment and can not be done very long and wide;

(4) Improper operation is easy to damage: improper operation of the installation personnel is easy to cause damage to the soft circuit, and its solder and rework require trained personnel to operate.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote