+86 134 0021 8776

+86 134 0021 8776

News

Jun. 16, 2023

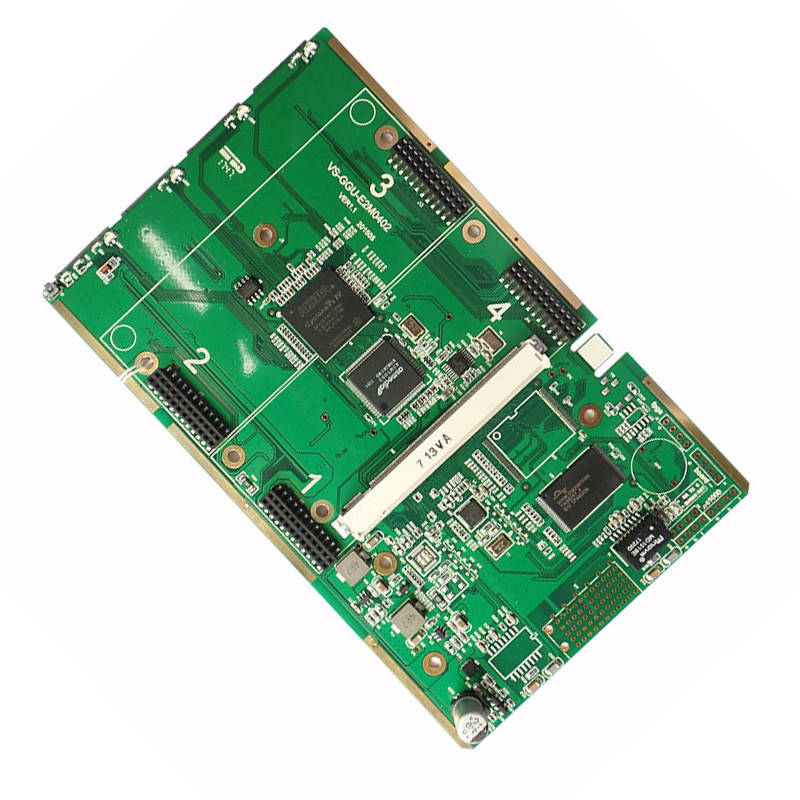

PCB- Printed circuit board

PCB stands for printed circuit board only. It is a circuit board that uses things like pads and conductive traces to connect electronic components electrically. On top of that, other features can be etched from the copper foil and then laminated onto a non-conductive substrate made of glass epoxy.

PCB can be divided into many signal layers, namely 4, 6 or 8 layers. However, the most common are 4 and 6 stories. PCB patterns can have different designs. For example, a printed circuit, a printed component, or a combination of both.

Alternatives to PCBS are point-to-point structures and winding, but these are rarely used. Laying out circuits on a PCB takes a lot of effort. However, this process can be automated for mass production. The board substrate is usually made of a dielectric composite material. These materials can be reinforced with epoxy resins and other materials, such as fiberglass or paper.

Type of printed circuit board

Single-layer PCB

Single-sided PCB. This is the most common and simplest form you can find in electronics. The reason is that it is easy to produce because it has a simple design. Single-layer PCBS contain only a single layer of conductive material, mainly copper. Using a solder mask protects the PCB from oxidation. In addition, single-layer PCBS are mainly used in the mass production of equipment such as radios, calculators and printers.

Double-layer PCB

Double-layer PCBS are also commonly known as double-sided PCBS. It comes with a layer of conductive material that applies to the top and bottom of the board. The main advantage of a double-layer PCB compared to a single layer is that it has a reduced size and enhanced flexibility, which makes the circuit compact. Dual panels are primarily used in telephones, industrial controls, amplifiers, UPS systems, HVAC applications, converters, and power monitoring units.

Multi-layer PCB

Multilayer PCBS with more than two conductive layers. In addition, the plate is designed to prevent overheating from causing damage to it. This is usually done by sandwiching glue between the insulation layers. Multilayer PCBS are mostly done in complex systems such as GPS technology, satellite systems, medical devices, data storage devices, and file servers.

PCBA- Printed circuit board assembly

PCBA refers to the process of filling a PCB board with various components, such as capacitors, integrated circuits, transformers, resistors, or any other components required depending on their purpose. You can also refer to it as the process of passing the PCB through surface mount technology and electroplating through holes. These two processes are essential because they allow the components to be welded to the blank plate. Some of these processes include reflow soldering, solder paste printing and component mounting.

Components of PCBA

An empty PCB board must be equipped with electronic components so that it can form a working PCBA. Through hole technology is used to mount these components on holes. In addition, these holes must be surrounded by conductive pads so that the entire board can function. The pins of the component are aligned on one side of the component using SMT, while the part is secured on the other side.

The two main ways to integrate components on a PCB are DIP and SMT. In a DIP, you need to drill holes so that the pins of the components you add can be inserted into that hole. However, SMT (surface mount technology) requires a mounter.

Discrepancy

The main difference is that PCB is a bare board, while PCBA is the process of refilling the board with electronic components such as integrated circuits and capacitors. After printing the solder paste and installing the components, you will have a PCBA (Printed Circuit Assembly). In order to establish a mechanical connection, reflux furnace heating is performed.

Without embedded components, PCBS cannot be used to manufacture electronic devices. Therefore, PCBA is the end product integrated in the production process of these devices. However, they go through an inspection and rectification process in order to correct any errors. PCBA is made from finished circuit boards. So without PCB, there can be no PCBA.

Previous: Basic requirements for qualified PCB circuit boards in in China

Next: Working principle and packaging form of NPN transistor

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote