+86 134 0021 8776

+86 134 0021 8776

Mar. 05, 2025

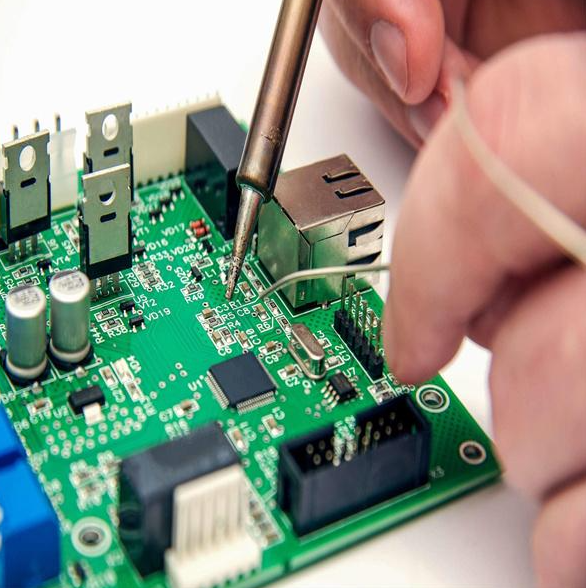

In the field of electronics manufacturing, the welding of PCB (Printed Circuit Board, printed circuit board) is a crucial process. The correct welding temperature and time can not only ensure the welding quality, but also improve the reliability and stability of the product. So, what are the requirements of PCB welding temperature and time?

First, the importance of welding temperature

The welding temperature directly affects the fluidity and wettability of the solder and the quality of the welded joint. If the temperature is too low, the solder may not be able to fully melt, resulting in weak welding, virtual welding, cold welding and other problems; The temperature is too high, it may damage the electronic components on the PCB board, deform the circuit board, and even lead to solder oxidation, affecting the welding quality.

Second, the temperature requirements of different welding methods

※Hand welding

For common soldering iron manual welding, the general welding temperature is between 300℃ and 350℃. This temperature range allows the solder wire to melt quickly and ensures good wettability.

During the welding process, the welding time should be adjusted according to different components and the size of the welding disc. Generally speaking, the welding time of small components is about 2 to 3 seconds, and large components may take 3 to 5 seconds.

※Crest welding

Wave soldering is a kind of welding method with high degree of automation, which is suitable for mass production. The temperature of wave soldering is usually between 245 ° C and 265 ° C.

This temperature range can ensure that the solder can fully wet the pad and component pins on the PCB board under the push of the wave crest to form a good welded joint.

The time of wave crest welding mainly depends on the speed of the conveyor belt and the height of the wave crest. In general, the speed of the conveyor belt is

between 1.2 and 1.8 meters/minute, and the welding time is about 3 to 5 seconds.

※Reflow welding

Reflow welding is a common welding method in surface mount technology (SMT). The temperature curve of reflow welding is divided into four stages: preheating zone, holding zone, reflow zone and cooling zone.

The temperature of the preheating zone is generally between 100 ° C and 150 ° C, and the purpose is to slowly heat up the PCB board and components and reduce thermal shock. The temperature of the insulation area is between 150 ° C and 180 ° C, mainly to let the solvent in the solder paste volatilize and prevent the solder paste from splashing. The temperature of the reflux zone is the key in the entire welding process, generally between 210 ° C and 240 ° C, which can make the solder paste fully melt and form a good welded joint. The temperature of the cooling zone is gradually reduced, so that the welding joint can be cured quickly and the welding quality can be improved.

Third, Influencing factors of welding time

※Component type and size

Different types and sizes of components have different welding time requirements. Generally speaking, the welding time of small components is shorter, and the welding time of large components is longer.

For example, the welding time of small components such as patch resistors and capacitors can be controlled at about 2 to 3 seconds, while for larger electrolytic capacitors and inductors, it may take 5 to 8 seconds to weld.

※Pad size and shape

The size and shape of the pad also affect the welding time. Generally speaking, the larger the pad, the longer the welding time.

For example, for ground pads with large areas, the welding time needs to be extended appropriately to ensure that the solder can adequately wet the pad. For complex pads, such as special-shaped pads, it may be necessary to control the welding time more carefully to avoid poor welding.

※Solder type and quality

Different types of solder have different melting points and fluidity, so the requirements for welding temperature and time are also different.

For example, the melting point of lead-based solders is low, and the welding temperature and time are relatively short; The melting point of lead-free solder is higher, requiring higher welding temperature and longer welding time. In addition, the quality of the solder will also affect the welding effect, good quality solder fluidity, welding time can be appropriately shortened.

※Welding equipment and process

Different welding equipment and processes have different controls on welding temperature and time.

For example, the use of advanced welding equipment can more accurately control the welding temperature and time, improve the quality of welding. At the same time, reasonable welding process parameter Settings, such as preheating time, welding speed, etc., can also affect the length of welding time.

Fourth, how to ensure the correct welding temperature and time

※Select the right welding equipment

Select the right welding equipment according to different welding requirements. For example, for manual welding, you can choose a good quality, stable temperature soldering iron; For high volume production, you can choose a high degree of automation of wave soldering or reflow welding equipment.

※Use a temperature measuring tool

During the welding process, temperature measuring tools, such as thermometers, temperature curve testers, etc. are used to monitor the welding temperature in real time to ensure that the temperature is within the appropriate range.

※Conduct welding test

Before the formal production, the welding test is carried out to determine the best welding temperature and time. The most suitable welding conditions can be found by adjusting the parameters of the welding equipment and changing the type of solder.

※Train operators

Training for welding operators, so that they understand the importance of welding temperature and time, master the correct welding methods and skills.

The correct welding temperature and time is the key to ensure the quality of PCB board welding. In actual production, we need to reasonably adjust the welding temperature and time according to different welding methods, component types and sizes, solder types and other factors, select the right welding equipment and process, ensure welding quality, improve product reliability and stability.

Previous: PCB substrate material selection considerations decomposition

Next: PCB circuit board welding temperature and time requirements

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote