+86 134 0021 8776

+86 134 0021 8776

Jul. 15, 2022

Since the COVID broke out, the chip become short globally.

From last year 2021, the chip price skyrocketed all over the world.Some chips' price increased by 5 times or 10 times, and some chip's price rose from several US dollars to several hundred US dollars, even to thousands of US dollars. It's lucky that there is stock, and for some chips, even you can pay for it for any price, but no stock.

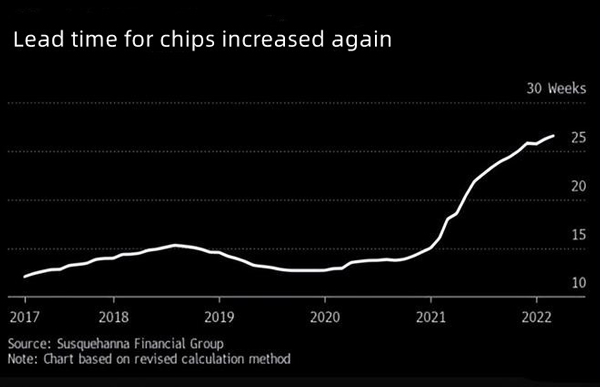

In 2021, the growth rate of the global chip market reached a record of 26.2%. The strong demand for chips and the factors of rising prices doubled the revenue and profits of major chip suppliers. But at the same time, the delivery date of the chip has been delayed again and again. According to statistics, since March 2021, the chip delivery time has been extended to 15 weeks for the first time, and has been extended to 26.5 weeks in March this year. On average, buyers have to wait for more than half a year to get the chips from factory, another record.

According to the data from a market research institution, the delivery time of all kinds of chips in the first quarter of 2022 was generally more than 12 weeks, and the price also showed a general upward trend. Specifically, the delivery time of analog chips is currently 12-52 weeks, that of connection chips is currently 18-52 weeks, that of storage chips is currently 12-54 weeks, and that of power devices is currently 16-52 weeks.

A small chip, the shortage storm swept the world. When will the shortage of chips be alleviated?

One analyst said that events such as the conflict between Russia and Ukraine, the epidemic and the Japanese earthquake will not only have a short-term impact on chip supply in the first quarter, but also may have a sustained impact on semiconductor supply throughout the year. It can be predicted that the core shortage will continue in 2022, while the demand in automobile, data center, industry and other fields is strong, and the shortage may be more serious.

The shortage of the chip is not the most serious problem. What is more difficult is the continuous rise in chip prices.Many large semiconductor companies have been raising prices continuously since 2021.It brought more pressure for the manufacturers in different industries.

The chip shortage situation will continue until 2023, then the chip demand of some customers can be fully met. Although IDM and wafer foundries in the semiconductor industry have made efforts to expand their production capacity this year, the new production capacity of some wafer factories will not be put into operation until the second half of this year.

For manufacturers in various industries, the only way to solve the problem is to actively respond and prepare goods in advance. After all, it is not a failure to live until the chip returns to the balance of supply and demand and the price returns to a reasonable one.

Previous: How to control the PCB assembly quality?

Next: None

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote