+86 134 0021 8776

+86 134 0021 8776

Sep. 18, 2024

First, Abstract

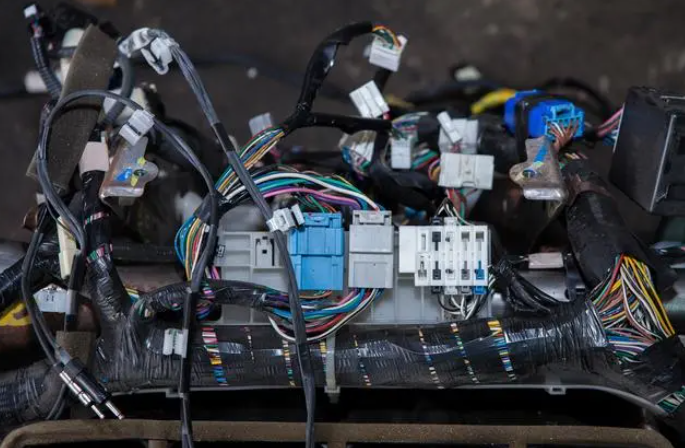

Automotive wiring harness is a key part of automotive electrical system, involving the transmission of electrical energy, signals and control instructions. This paper introduces the production process of automotive wire harness, including raw material selection, processing, inspection and testing, each link needs to be strictly controlled to ensure quality and performance. The continuous development of automotive technology presents more challenges and opportunities for wire harness production, but we believe that through innovation and improvement, automotive wire harness production will be more efficient, accurate and reliable.

Automotive wiring harness, as an important part of automotive electrical system, carries the key tasks of transmitting electric energy, signals and control instructions. With the development of automotive technology, the complexity and accuracy requirements of automotive wiring harnesses are also increasing. This article will give you an in-depth understanding of the production process of automotive wire harnesses, from the selection of raw materials to the inspection of finished products, and explore the mysteries of wire harnesses manufacturing.

Second,Selection and preparation of raw materials

The raw materials of automotive wire harness mainly include wires, insulation materials, connectors and so on. The choice of these raw materials is directly related to the quality and performance of the wiring harness.

1.Wire: Wire is the basis of wire harness, its material, cross-sectional area and conductivity directly affect the transmission capacity of wire harness. The commonly used wire materials are copper, aluminum, etc., and the cross-sectional area is selected according to actual needs.

2. Insulation materials: Insulation materials are used to wrap wires and prevent short circuits between wires. Common insulation materials are polyvinyl chloride (PVC), polyethylene (PE) and so on.

3. Connector: Connector is an indispensable part of the wiring harness, it is responsible for connecting different wires to achieve the transmission of electrical signals. The selection of connectors should consider their electrical properties, mechanical properties and environmental resistance.

Third, harness processing and production

Wire harness processing is the core of wire harness production, mainly including the following steps:

1. Wire cutting: According to the design drawing of the wire harness, use special cutting equipment to cut the wire to a suitable length.

2. Wire peeling: Use a wire stripping machine to peel the insulation layer at both ends of the wire to expose the internal metal wire core.

3. Wire crimping: crimp the peeled wire with the connector to ensure a good electrical connection between the wire and the connector.

4. Wiring harness assembly: Assemble the crimped wire according to the requirements of the design drawings to form a complete wiring harness.

4.Wiring harness fixing: Use cable ties, fasteners and other fixed parts to fix the wiring harness on the car to ensure that the wiring harness will not loosen or fall off during use.

Fourth, harness inspection and testing

In order to ensure that the quality and performance of the wiring harness meet the requirements, the wiring harness must be strictly inspected and tested. Inspection and testing mainly include the following aspects:

1. Appearance check: Check whether the appearance of the cable harness is smooth, without damage, and without exposed metal cores.

2. Electrical performance test: Use special test equipment to detect the electrical performance of the wire harness, such as resistance, insulation resistance, voltage resistance, etc.

3. Mechanical performance test: test the tensile strength and bending properties of the wire harness to ensure that the harness can withstand various stresses during use.

5.Environmental adaptability test: Simulate the use of cars in different environments, and test the performance of wire harness such as temperature resistance, humidity resistance and salt spray resistance.

Fifth. Conclusion

The production process of automotive wire harness is a complex and fine process, involving the selection of raw materials, processing, inspection and testing. Each link needs to be strictly controlled to ensure that the quality and performance of the wiring harness meet the requirements. With the continuous development of automotive technology, the production of automotive wiring harnesses will also face more challenges and opportunities. We believe that through continuous innovation and improvement, the production of automotive wiring harnesses will be more efficient, accurate and reliable, providing strong support for the development of the automotive industry

Previous: Research on automotive wire harness materials

Next: Uav market prospect

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote