+86 134 0021 8776

+86 134 0021 8776

Feb. 26, 2025

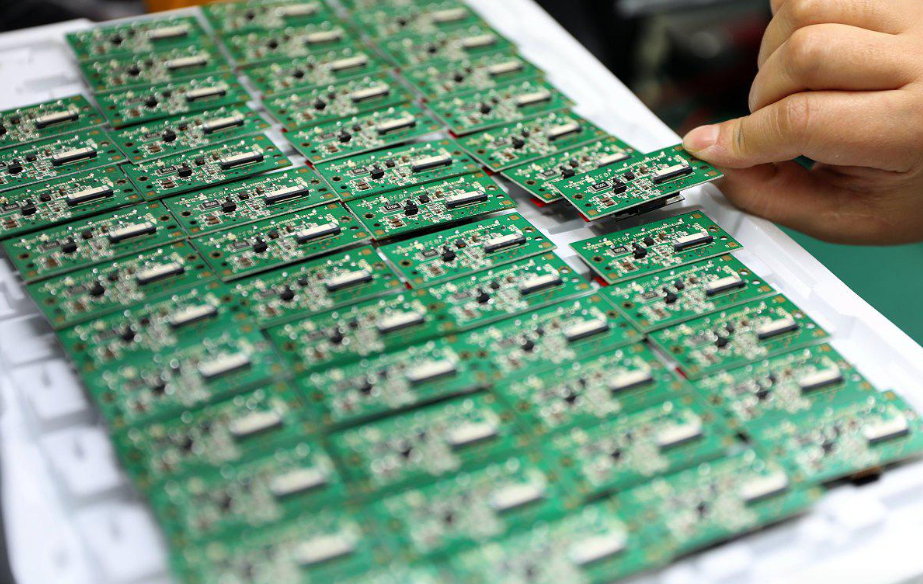

PCB (Printed Circuit Board) factories usually need to use different types of inks to meet various printing tasks and requirements. Some common PCB printing ink types are described in detail below:

Carbon ink: Carbon ink is a common PCB printing ink, which is composed of carbon particles, solvents and additives. Carbon ink is mainly used to print conductive patterns on PCBS, such as circuit paths and pads. It has good electrical conductivity and reliability.

Silver ink: Silver ink is a PCB printing ink with good electrical conductivity. It usually consists of silver particles, solvents and stabilizers. Silver ink is used to print conductive patterns with high accuracy and reliability. Since silver is an excellent conductive material, silver ink is preferred in many applications.

Carbon-silver ink mixture: Carbon-silver ink mixture is a PCB printing ink that mixes carbon ink and silver ink. It combines the properties of carbon and silver inks to provide better electrical conductivity and applicability in certain situations.

Copper ink: Copper ink is a PCB printing ink containing copper particles. It is mainly used for printing conductive patterns that require high current and high heat dissipation requirements. Copper ink plays an important role in high power electronics and high frequency applications.

Isolation inks: Isolation inks, also known as shielding inks or solder resistance inks, are used to form an insulating layer on the PCB to stop the flow of current or protect circuit elements. Isolation inks usually have insulating properties, heat resistance and chemical corrosion resistance.

Heat-resistant inks: Heat-resistant inks have high heat resistance and can withstand high temperatures during the manufacturing process of the PCB, such as baking and welding. This ink can maintain stability and is not affected by high temperature treatment.

Antioxidant inks: Antioxidant inks are used to provide antioxidant protection on PCB surfaces to reduce corrosion and damage to circuit components. It can effectively prevent oxidation reaction and maintain the stability and reliability of the circuit.

It should be noted that the specific ink used depends on the PCB factory's requirements, design specifications, and the required functions and performance. Different PCB manufacturers may work with different material suppliers and use specific ink formulations, so there may be some differences and variations in practical applications.

Previous: What is the principle of wire and cable? Why is it able to transmit electricity and signals?

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote